Since the dairy industry did me the diservice of changing the shape of milk crates to not hold LP records properly before I was born, I've never been able to just pick up a crate to keep my records in. The cheapo bins from Wal-Mart are fimsy and I wanted something better but didn't feel like messing with replacing the flimsybin enough to make something.

Then yesterday my stepmom mentioned wanting a bike basket after seeing my bike rack. I made one out of the same blue news stand mesh, 12" by 9". When I brought it inside and set it down by my record collection though I realized it was the right size to hold records. I had to make more of these to keep my LPs in.

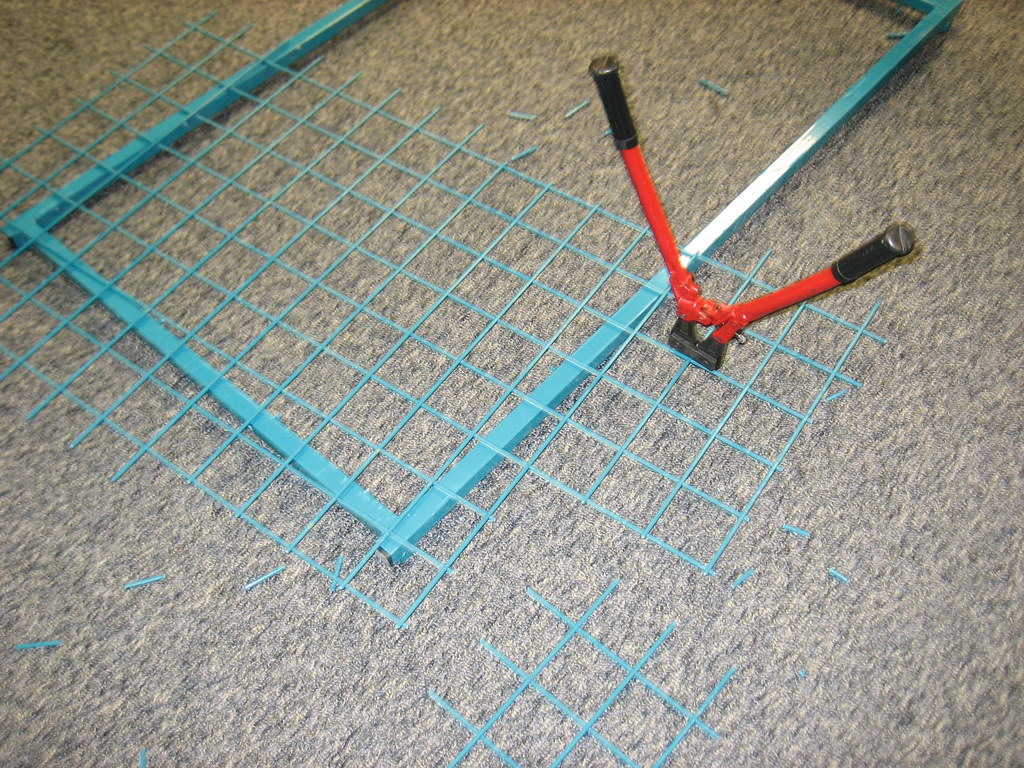

The construction is pretty easy. Cut out a lopsided or even sided T with at least one dimension of the middle being 12". then fold, beat, and bang the sides up and into place, holding them down with zip ties for a little extra support. They turn out nice and hold about 50 records each. I made a full out Instructable here. It got featured on the Instructables homepage, kinda neat to have happen.

Since I commandeered my stepmom's basket (the initial one) I made a couple more so she'll still have one.