A few years ago I got into old arcade video games. They repre

sented a time that I wasn't a part of which seemed to have it's own story with dimly lit caves full of kids and teenagers who were free to roam around and try their hand at besting rows of machines that would entertain and cast a cool light over their faces until the quarters were gone and their three initials had been etched into the game's record of heroes. It seemed (and still seems) a shame to me that these places of social video games are slowly fading away, and I wanted to have a part of that time. I looked into it and found that much like home video game systems like the

NES, Sega Genesis, and Atari have been translated into programs that emulated their games for modern computers, arcade games have much the same thing going for them with a program called

MAME (the Multiple Arcade Machine Emulator). I was able to not only play something similar to those original arcade games, but actually play the originals, their code and idiosyncrasies pulled straight from their original game boards and loaded for me to play on my PC, even down to having to press a button to "feed" the game a quarter.

For a while this was very interesting and fun, but it still wasn't the full experience of standing in front of a real arcade machine and mashing buttons and joysticks. I looked into MAME's community more and found that there were already

many other people, maybe hundreds, who had the same want for a full arcade machine in their home that I did, and thanks to the Internet, they had gotten together to share stories of how they made it happen and what they did along the way. Some people had gotten old arcade games and fitted a computer to the original screen and joysticks; others had started from scratch and build their cabinets, ordered brand new controls to use in their machines. Some had used old keyboards and PC joysticks with a rat's nest of wires connecting everything while others had come up with or used very professional looking, very clean machines that were custom designed for their purpose. Many people had created huge four player behemoths that have every controller from every arcade game one could imagine while still others had created coffee table sized machines that were best suited to earlier, more simple games. I was hooked on the idea of having my own.

I poured over every instruction page, build log, and relevant site I could find, trying to figure out the best way for to go about bringing this idea to life. I slowly collected parts that I thought would be useful and saved my pennies for either buying a gutted/dead game or buying the materials to build my own. I happened upon a dealer at

the local flea market who sells video games and used to work with arcade games. He had a few boxes of old controls which I bought, along with a marquee panel for

Robotron 2084. Most of these had 20 years worth of grime, grunge, and cigarette burns from having spent as much time in arcade games and parts bins. I managed to salvage and clean enough controls to get a full set of control for 2 players. I still didn't have a cabinet to put them in though.

After a false start with someone on eBay selling me a cabinet for cheap, but refusing to ship it, I decided it would be best to build my own rather than wait to happen upon one locally. I decided to go with a design called

LuSiD's Arcade Flashback. It's large, and gave plenty of room for the needed parts, as well as being fairly simple to construct. A friend of my dad who's a fantastic carpenter helped me construct the cabinet out of Melamine backed MDF. It's a type of particle board often used on counter tops, and was what many people used for their cabinets since it's got a nice smooth surface. The problem was that it's hard to work with. You have to pre-drill all holes and glue all screws and seams together or you risk the materials breaking apart. It also weighs a ton and has nice sharp edges, so any time it would slip it would cut me. With the help of my dad's friend these concerns were minimized and in the end the cabinet went together as planned, with a few additions such as a piano hinge on the control panel to make adding controls easier down the line and a slot for the marquee to slide into so that I could easily swap it later if I wanted to. I had construction photos for the cabinet, but they may be lost to the digital sands of time.

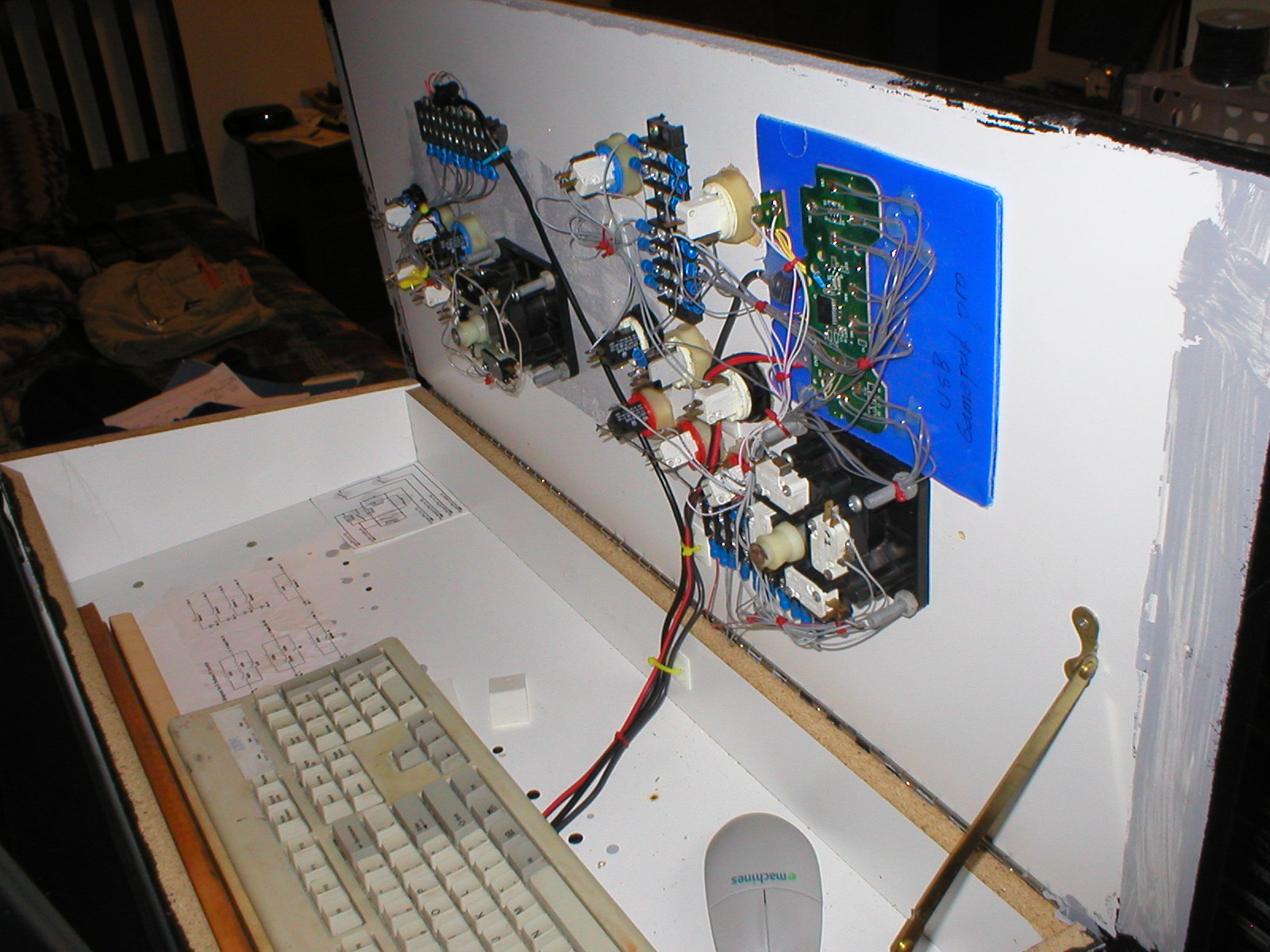

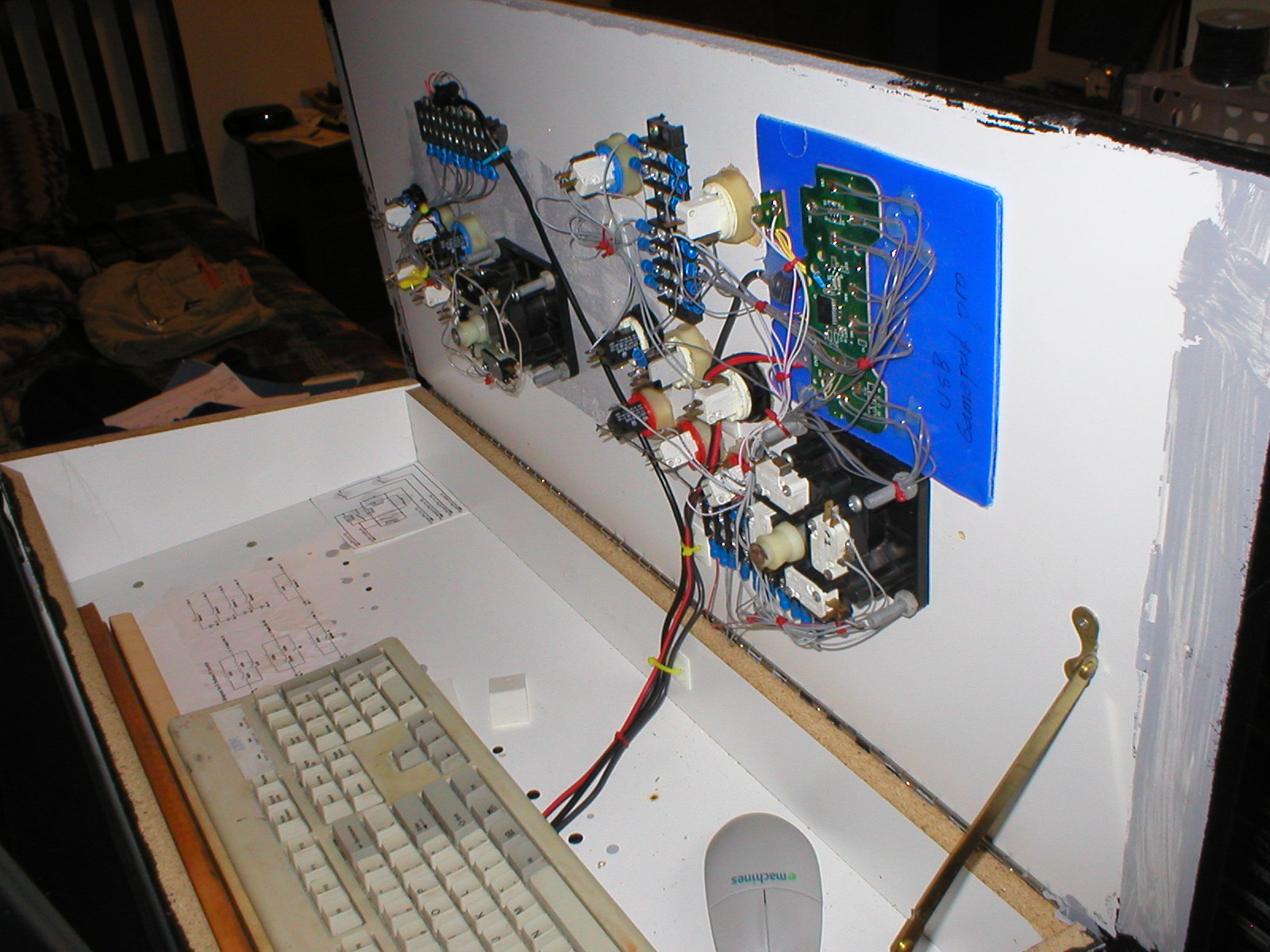

Now that I had all the major parts ready, I began putting t

hings together. I cut a clear plexi cover for the control panel and mounted the controls, wiring only one side since I still wasn't sure how I was going to set up the second set. Then I scrapped together a computer from my parts bin and set the huge 19" monitor an uncle had given me in place only to find out the case was too large for my cabinet. I removed the plastic case over the screen and that made the clearance just right.

Once I got the cabinet up and running in a basic sense it sat unfinished for some time until I got the urge to work on it more. This time I took it apart, painted everything one cold morning, and then rewired the controls, this time hacking up a USB game pad to allow me to wire all the controls, though I left a few of the P2 buttons unfinished. I also added a large Donkey Kong decal to the side so I would have some side art rather than a blank black cabinet. For a marquee light I used whatever I had most available. At one time that was a nice florescent lamp, which was later repurposed, giving way to duct tape and a desk lamp, which I didn't like the idea of after a short while. I replaced that with a florescent tube powered by the driver circuit from a CFL bulb. This idea later became the idea I also used in

the lightbox a friend and I made.

That was how the arcade cabinet usually went for a couple years. I'd work on it once in a while, slowly scrapping together better pieces and a better computer, but it would generally stay in some state of disrepair and general untidiness. At one point another uncle of mine, knowing I was working on this, brought me a very beat up, damaged, and barely working

N.A.R.C. cabinet, from which I finally got a coin door to put in the cabinet as well as some other working parts. I'd snag a part from the computer to feed another project or the control

s would snag a loose wire while playing and kill one or more buttons. Eventually I got tired of such things though and decided to fully finish it. I wired all the controls properly and cleaned up the rats nest that had developed beneath the control panel, made a bezel to go around the screen and shroud the less than clean paint job behind it, and set up MAME with a pack of several thousand games and made sure the settings allowed you to control as much of the system as possible with the arcade controls.

Everyone who saw or played with the cabinet liked it (especially when it was working properly), but since I'd had it a couple years now and I'd long since appeased my bug to have a full-sized arcade machine I started thinking about how much I needed the space the cabinet took more than I needed the cabinet. I also felt somewhat bad for having it and using it as little as I did since the time I first got it going.

I posted the machine on

CraigsList, hoping to pass it along to someone who would get more use and fun out of it, and after letting it sit for about a month, a kid about the same age I was when I started looking into MAME offered me more than I'd ever put into the cabinet (not counting labor time of course). I was happy to see it move on to someone who would get some fun out of it, and it seemed like it was passing full circle since before the kid (I say kid, he wasn't more than 5 years younger than me) and his dad left, I heard them already talking about how big it was and trying to figure out how to find somewhere to put it; a discussion my dad and I had when he first saw how large the empty cabinet really was.

It was really an enjoyable project, and I really learned a lot about wood working, electronics, soldering, how things like video games were made in the past, and how computer interfacing could be done. I might get a taste to make a newer machine some day, but it would definitely be much smaller (something that could fit on a counter top) and likely be made of normal plywood. If anyone reading this would like more information about this machine or anything related to it's construction, please leave a comment. I'd love to be able to give back to the community that helped me make a piece of video game history come to life for me.